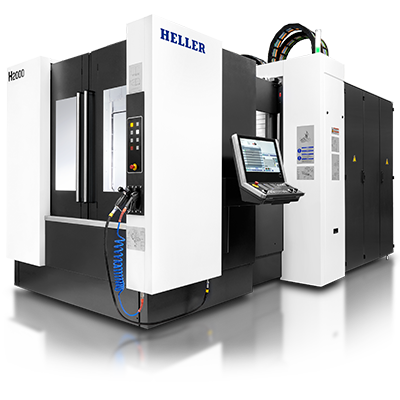

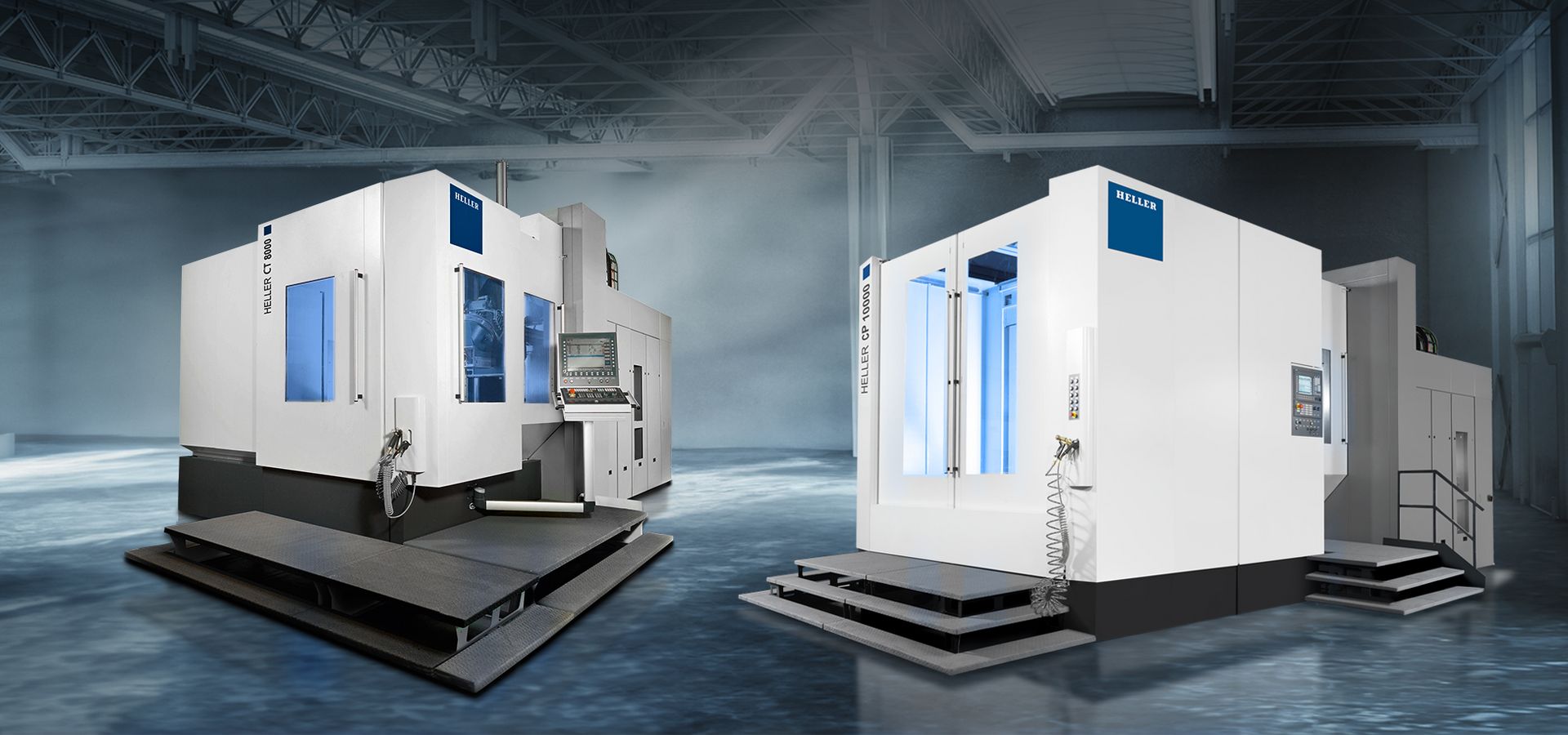

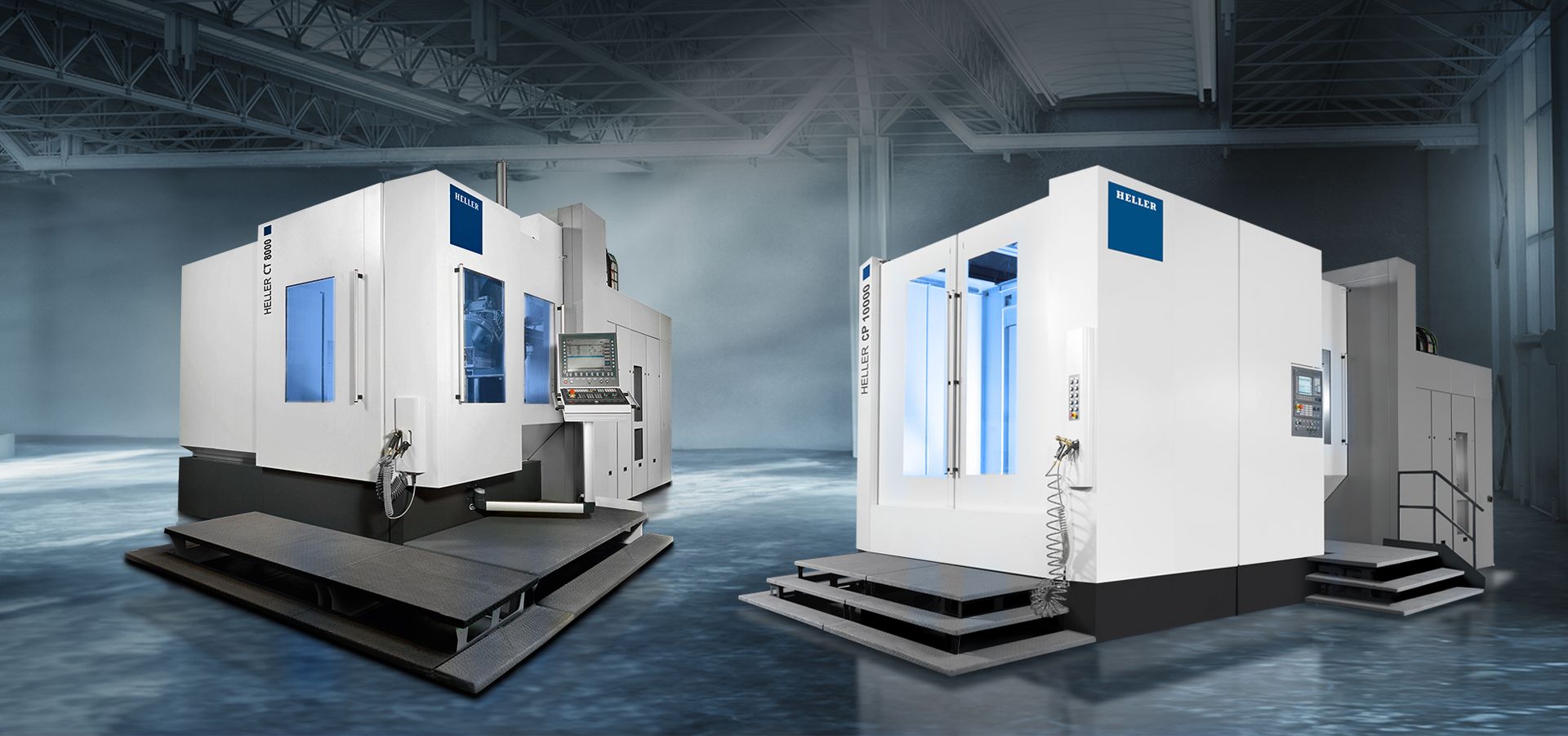

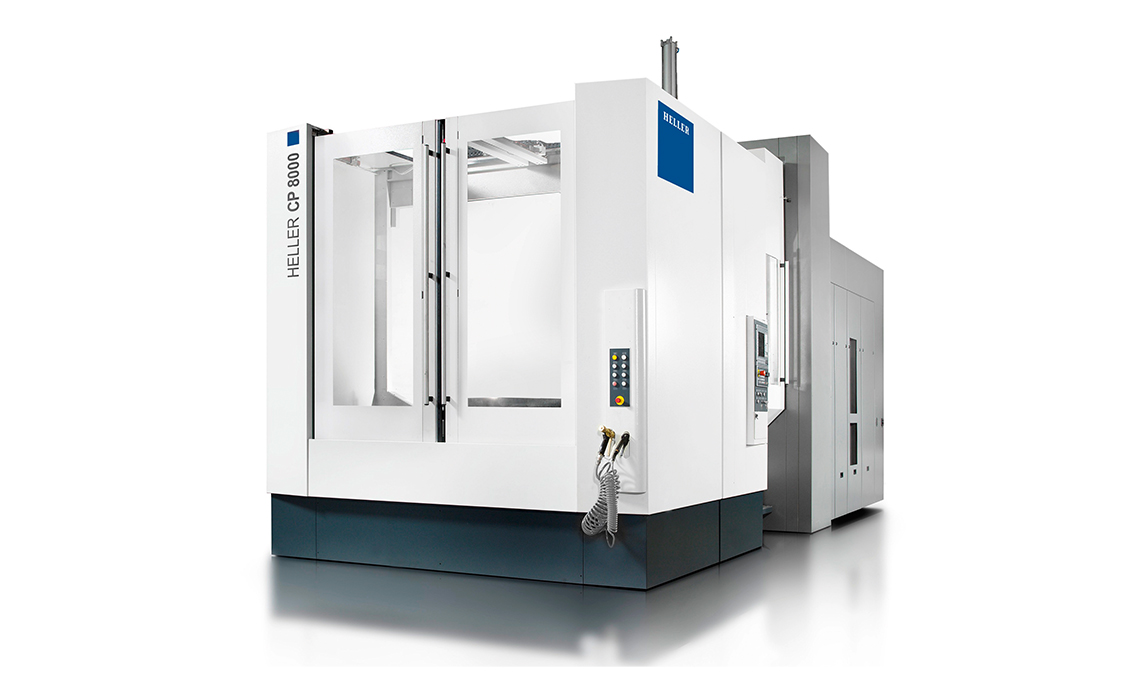

Machine concept

Structural dynamic examinations as early as the development phase are key to a milling-turning machining centre achieving an equally high performance in both the milling and turning machining strategies. Both the machine concept and the entire process design of our C-series 5-axis milling-turning machining centres are the result of a comprehensive simulation process. For you, this means: reliable productivity and precision in two fully-fledged production processes.

Cross-bed and travelling column in gated design

- high stability and damping in the flow of forces through topology-optimised structural components from cast iron

- thermo-symmetrical design and optimized flow of forces

- broad range of machining units in a robust design

- tool changer with two NC-axes for fast automatic tool change

- large range of tool magazines, chain or rack-type

- machines with integrated pallet changer (CP) and high payload for fast automatic pallet change

- machine variant with table loading (CT) available for selected sizes

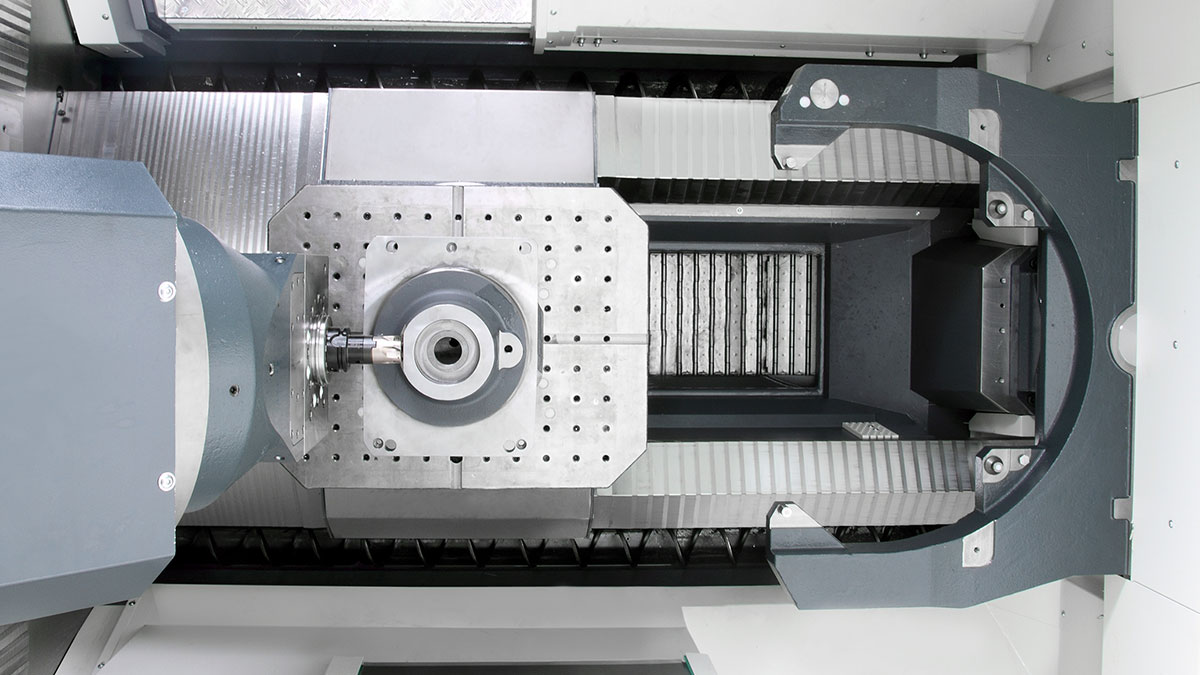

5-axis kinematics with horizontal basic alignment and a 5th axis in the tool

- machine bed carries the X- and the Z-axis in a cross bed arrangement

- the machine column traverses in the X-direction and carries the machining unit

- machining unit traverses in the Y-direction, compactly integrated into the machine column in a stable manner

- rotary table traverses in the Z-direction and executes the feed movement

- NC rotary indexing table (B rotary axis) turns the workpiece continuously (360.000 x 0.001°)

- swivel head (C) or tilting head (A) – the 5th axis is in the tool (max. C 345.000 x 0.001°/ A 175.000 x 0.001°) (swivel range with optional swivel range expansion)

Roller bearing-mounted linear guides and stable YRT bearings in the rotary axes

- linear axes driven by roll guides with ball screws for high feed forces

- direct, absolute measuring systems (glass scales in linear axes) for optimised precision and low position tolerance

- rotary tables with large YRT bearings and automatic clamping for maximum stability and high tilting moments

- directly driven DDT (Direct Drive Turning) for high speeds and dynamism

Spindle units

The requirements for a spindle in milling/turning machining centres could not be more different. Milling in full operation on the one hand, vertical, horizontal and positioned turning on the other. For our C-series, we have found a solution that allows you to reliably convert power and torque into action.

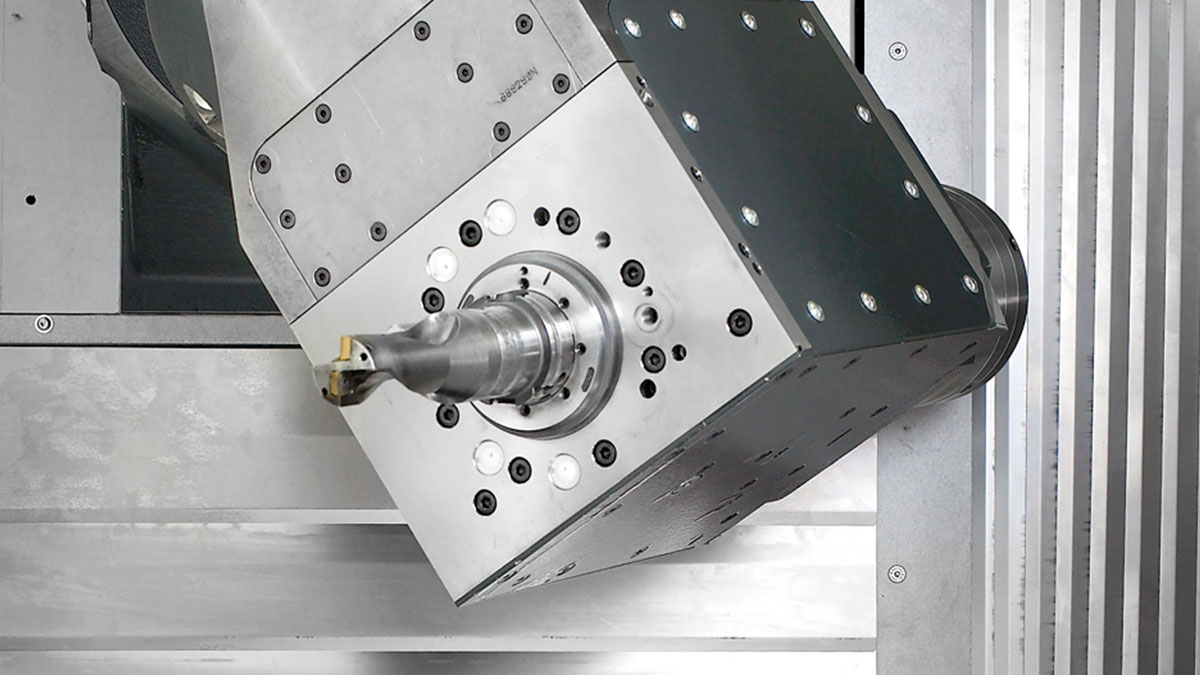

Broad range of powerful 5-axis machining units

- machining units with two kinematic variants for the 5th axis in the tool: Swivel head or tilting head

- rigid cast iron guide slide with high dynamic stiffness and damping

- thermal stability and precision thanks to permanent cooling: Precision cooling unit and thermal growth compensation for the spindle

- automatic clamping of the 5th axis during machining with positioned rotary axes

- tool shank HSK-T for maximum precision during turning

- integrated, automatic spindle locking for maximum stability during turning operations

Swivel head kinematics

- maximum performance in action thanks to stable swivel head kinematics

- compact design through 45° swivel head geometry

- high rigidity thanks to short distance between swivel head mounting and tool holding fixture

- swivel range between C +15° to C-190° (optionally expandable with swivel range expansion)

- energy and media routing integrated: No lines in the work area

Tilting head kinematics

- maximum flexibility with complex workpiece geometries

- simple programming and operation thanks to simple head geometry

- A-axis driven by two swivel motors and a braced power train

- swivel range between A +30° to A-120° (optionally expandable with swivel range expansion)

- energy and media routing integrated: no lines in the work area

4 powerful machining units

- torques of up to 1,146 Nm (S6 40 %)

- speeds of up to 12,500 rpm

- integrated spindle locking for turning operations

HELLER zero-spindle system for quick and easy spindle exchange

- spindle exchange without complex adjustments

- reduces the repair time

- cost-effective service solution

HELLER attachment head support (MSK)

- for use with adapter heads, e.g. angular heads

- enlarged location base with three-point location

- integrated torque absorption and media transfer

Swivel range extension

- swivel head from 205° to 345°

- tilting head from 150° to 175°

* not available for all machining units

Tool management

Complete machining with one milling/turning machining centre significantly reduces the part costs. However, combined processing presents a challenge for the tool management system: An extensive range of milling and turning tools must be available and loaded precisely and safely in the process. No problem for HELLER C-series 5-axis milling-turning machining centres.

Chain-type tool magazine for fast tool provisioning

- 3 chain-type magazines with up to 150 pockets to choose from

- rigid tool holder mounted on both sides of a double chain for high chain traversing dynamic

- tool setting station with optimum accessibility for ergonomic and fast tool setting

- integrated tool provisioning station for provisioning of the follow-on tool during machining and short tool-to-tool times

- tool shank in closed holders: protects against contamination and optimum hold during positioning

- tool provisioning during machining for short tool-to-tool times

Options

- convenient operating terminal at the tool setting station

- setting during machining

- tool coding with RFID chip

- tool shank cleaning, incl. cartridge flushing and drying

- HELLER TRP (Tool Requirement Planning) for automatic creation of loading and unloading lists

- tool break monitoring during machining

Rack-type tool magazine with high storage capacity

- 2 rack-type magazines with up to 425 pockets to choose from

- tool handling with highly dynamic loader for fast tool provisioning

- tool setting station with integrated rotary station with multiple tool pockets for setting during machining

- convenient operating terminal at the tool setting station

Options

- automatic rotary station

- tool coding with RFID chip

- tool shank cleaning with brush and flushing option

- HELLER TRP (Tool Requirement Planning) for automatic creation of loading and unloading lists

- tool break monitoring during machining

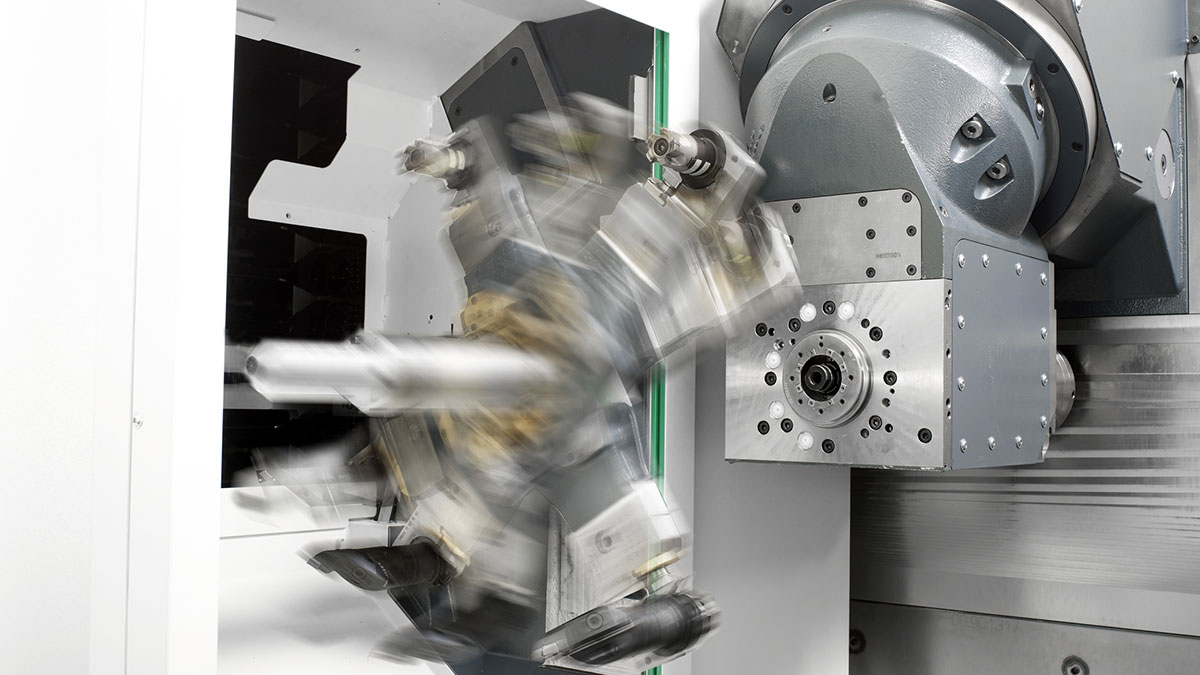

Fast tool change for short chip-to-chip times

- two NC-axes with lifting/swivelling principle for a high dynamic and continuous precision

- stable double gripper for secure hold with high tool weights and tool moments of weight

Workpiece management

You can of course configure the C-series 5-axis machining centre to suit your particular requirements: As a workshop machine with large work area, ideally suited for single part production or as a production machine with pallet changer and the corresponding automation solution for series production.

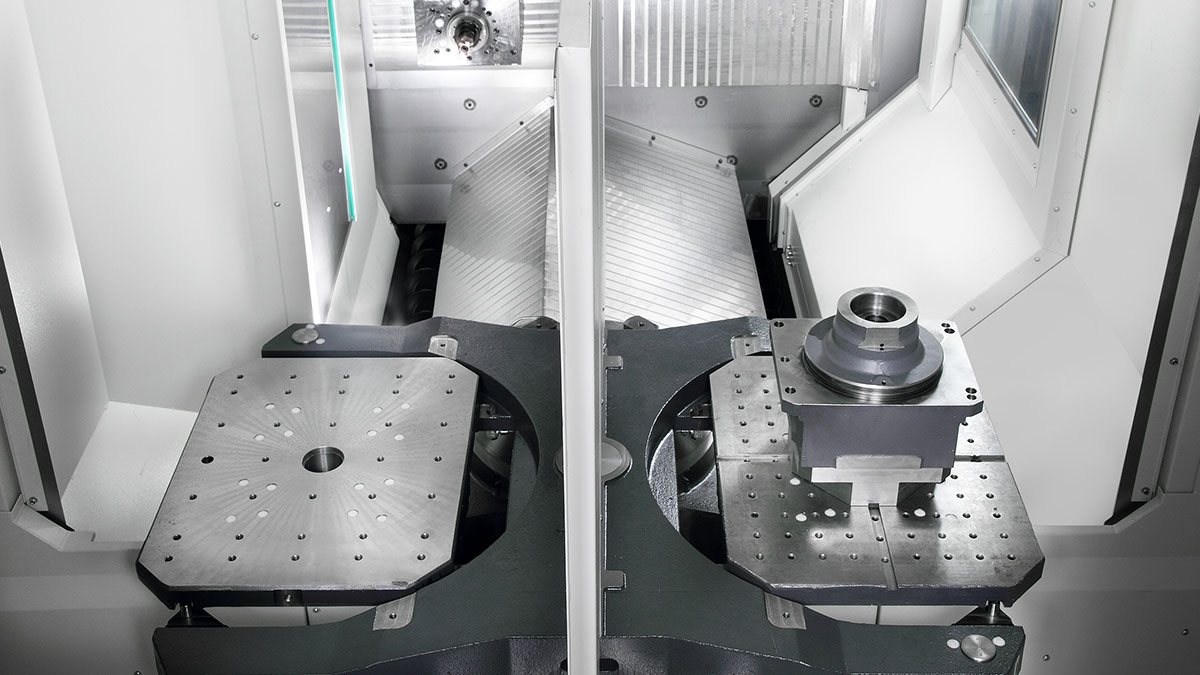

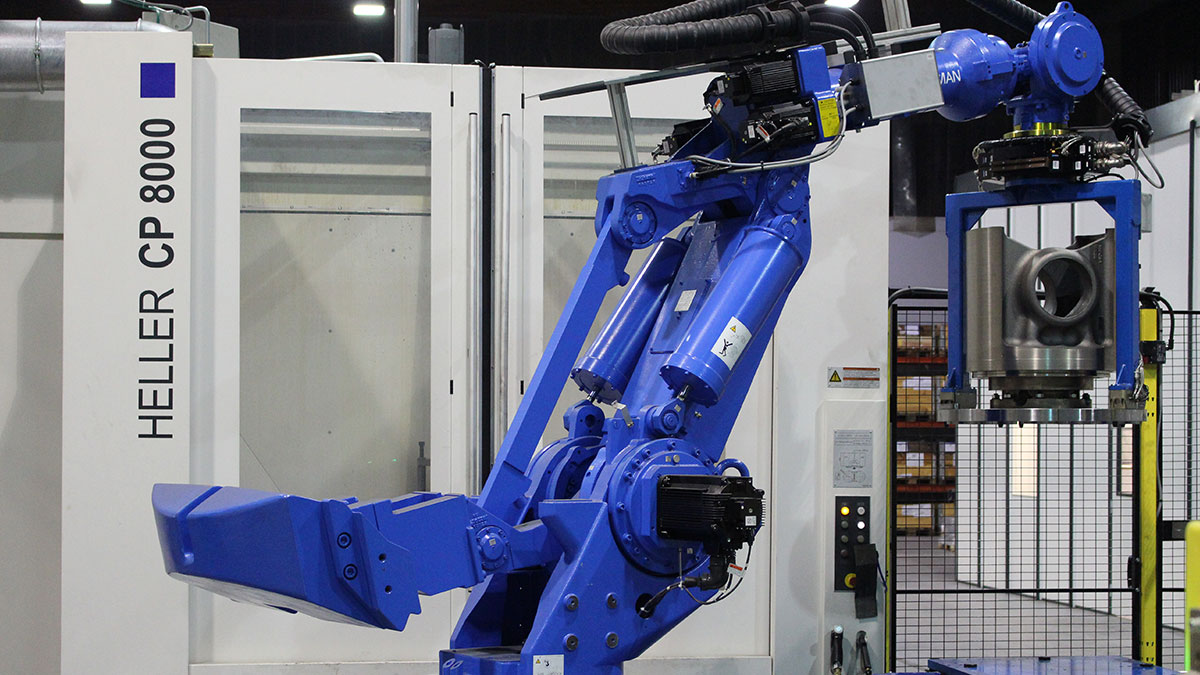

Pallet changers are optimal for series production

- automatic pallet changer with lifting/swivelling principle

- high maximum payload through robust, hydraulic drive

- optimised force application to machine pallets due to the fork shape of the lifting/swivelling traverse

- continuously high changeover accuracy through robust aligning elements and extensive blow-out of the function surfaces

- hydraulic pallet clamping for secure hold, even with high process forces

- machine pallets with DIN hole pattern and standardised aligning elements for fast mounting of clamping fixtures

Setting and loading during machining

- manual or automated loading by robot or pallet

- large smooth-running door to optimise access for loading and setting by crane or handling systems

- workpiece setting station, lockable at 90° indexing with foot unlocking mechanism, unrestricted manual rotation

- operating elements, as well as media guns within reach, integrated into the machine enclosure

Options

- integrated media interface for hydraulic workpiece clamping (60 bar)

- additional pneumatic functions: location check and unclamping check via media interface

- active operator support through automatic functions: Automatic setting station door, automatically rotating NC setting station, automatic setting and de-setting sequence

- machine pallets in DIN T-slot design

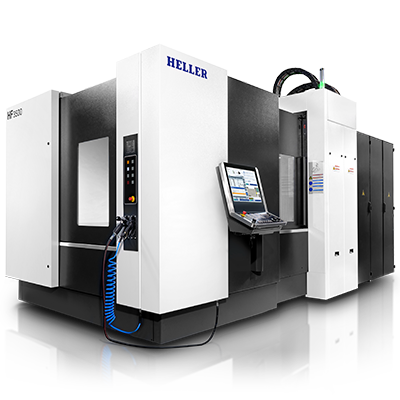

Table loading for workshop use

- workpiece loaded directly onto the machine table in the work area

- optimum accessibility to the workpiece thanks to integrated platform and low "loading edge"

- large, divided work area door opens wide to the work area for simple setting and crane loading of large components

- round machine table with large clamping surface and DIN hole pattern

- main operating unit designed as a console with 24" multi-touch screen, can be swivelled between operating station and workpiece setting station

- media guns integrated into the machine enclosure

NC rotary indexing table with rotary function

- rotary table with direct drive for high turning speeds and a high milling dynamic

- large YRT bearing for maximum stability and high tilting moments

- automatic hydraulic rotary table clamping for high tangential torques

- permanent cooling with separate cooling unit

- automatic imbalance detection during machining

- HELLER balancing cycle for simple setup balancing and imbalance check

Options

- integrated media interface for hydraulic workpiece clamping (60 bar)

- additional pneumatic functions: location check and unclamping check via media interface

- automatic setting station door

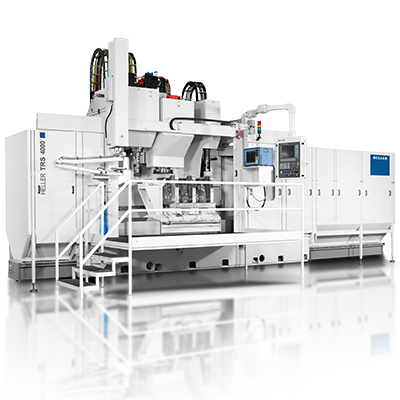

Automatisierung

Automation solutions from HELLER are individual concepts that we develop specifically for your production facility. We analyse your requirement and devise a solution that allows you to work to your maximum capacity. We use standardised solutions wherever possible. The C-series 5-axis machining centres are prepared for pallet and workpiece automation.

Storage of machine pallets and automated setting of one or multiple machines

- standardised linear storage systems with up to 15 storage locations depending on type and size (optional)

- standardised machine interface available for numerous machine sizes (option)

- everything from a single source: Complete solution for short installation time and commissioning

- optimal capacity utilisation with continuous pallet feed to one or multiple machines

- consequently, increased cost efficiency and more flexibility in the production facility

- specific advantages for production tasks with a large part mix and series production with small batch sizes

Options

- standardised host computer interface for optimal connection to the host computer

- high number of functions and options for automated production control

- media interface for hydraulic workpiece clamping

Automatic loading and unloading of workpieces

- workpiece handling by robot relieves the operator

- ideal solution for series production

- machining centre works to capacity thanks to continuous material feed

- standardised machine interface for robot loading onto the setting station (option)

Options

- media interface for hydraulic workpiece clamping

- location check and unclamp check

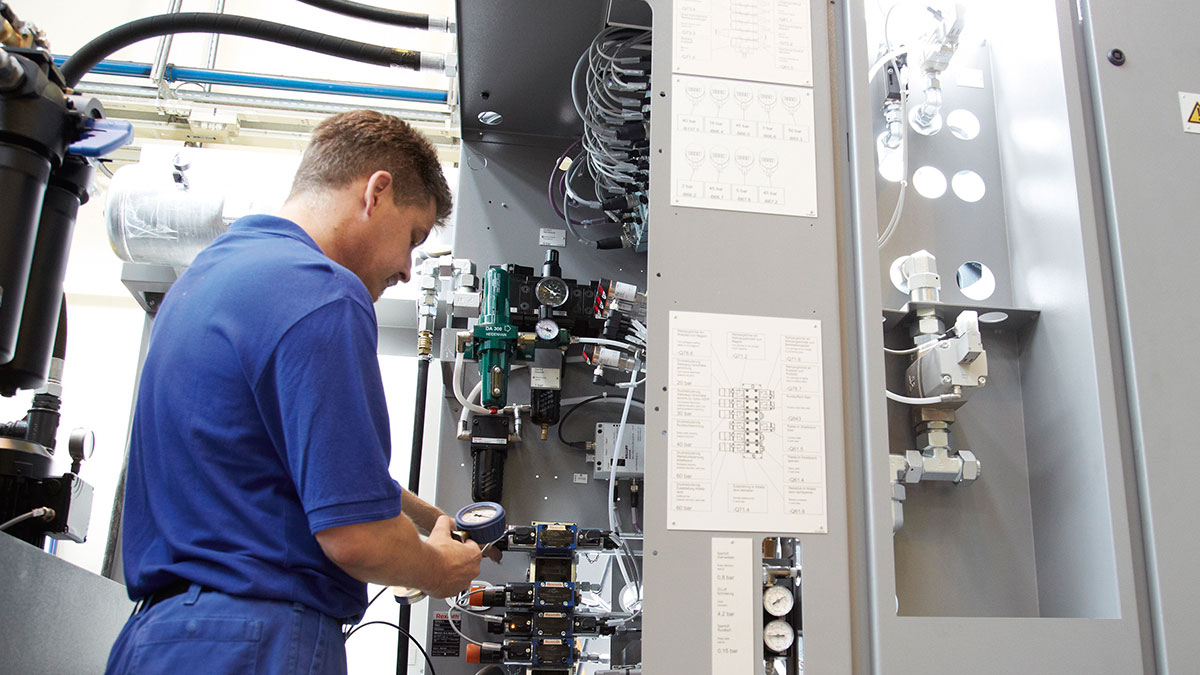

Central media supply area at the rear of the machine

- simple maintenance with optimum accessibility, all supply units at a glance

- compressed air and flushing gun integrated into the machine enclosure at the workpiece setting station

- centralised oil/air lubrication for the key components

- sealed air and selective blow-out of interfaces for permanently smooth machine operation

- media interface for hydraulic workpiece clamping at 60 bar or 200 bar (option)

Effective cooling lubricant supply and filtering

- coolant units: paper band filter or vacuum rotation filter with high tank volume optionally available

- internal coolant supply (IKZ) through the tool at high pressure 50 bar (option: 70 bar)

- internal coolant supply with up to 7 pressure stages freely programmable via the NC program

- external tool cooling with flushing nozzles integrated into the spindle

- integrated work area flushing with adjustable nozzles for optimal work area flushing and workpiece cooling

Options

- coolant cooler or coolant temperature control for high thermal stability and precision

- automatic filling of the coolant unit

- oil skimmer for removing foreign oil from the cooling lubricant tank by oil separation

Fast chip removal from the work area

- chip disposal using spiral conveyors and a cross-conveyor

- chip conveyor as either scraper conveyor or hinged conveyor, depending on the application (option)

- steep side walls and bellow covers with self-cleaning effect prevent chip deposits

- work area flushing and work area shower support fast chip disposal for machines with coolant units

- optional: exhaust unit for exhausting cutting fluid mist from the work area

Operation and maintenance

Milling and turning at the limit calls for maximum operator performance too: he must respond flexibly to new tasks at all times, change workpiece and tools quickly, yet still working safely. When developing the HELLER C-series, then, we considered simple operation, short distances and a high degree of comfort as paramount.

Optimal accessibility to all work areas for simple operation and maintenance

- operating comfort and ergonomic design increase productivity

- spatial separation between operating and maintenance areas

- robust operating elements for tough everyday production conditions

- smooth-running doors and easily removal metal enclosure elements

Maximum operating comfort during setting and production

- ergonomically arranged operating elements and control screens

- swivelling main operating unit with clamping function optimally integrated into the machine enclosure

- good view into the work area thanks to large safety screen

- smooth-running work area door with linear guide opens the work area roof in the operating area

- operating modes 2 and 3 included in standard scope of supply

Options

- handheld operating unit

- screen blow-off device for a clear view when machining with cutting fluid

- main operating unit in console design with 24" multi-touch screen and HELLER Operation Interface

Setting and loading during machining thanks to the pallet changer

- large smooth-running door to optimise access for loading and setting by crane or handling systems

- workpiece setting station, lockable at 90° indexing with foot unlocking mechanism, unrestricted manual rotation

- operating elements, as well as media guns within reach, integrated into the machine enclosure

Options

- automatically actuated setting station door

- automatically rotating NC setting station

- software options: automatic setting and de-setting sequence

Optimal accessibility for fast tool setting

- ergonomically arranged operating elements

- insertion location at optimum height and with integrated unclamping function for simple handling

- tool setting at the magazine when spindle is running

Options

- convenient operating panel at workpiece loading station

- setting during machining

- tool coding with RFID chip

- HELLER TRP (Tool Requirement Planning) for automatic creation of loading and unloading lists

Central supply area at the rear of the machine

- simple maintenance: all supply units at a glance with good accessibility

- smooth-running doors and easily removal metal enclosure elements

- simple and direct access to the control cabinet

- quick-response HELLER spare part service

Options

- maintenance manager for maintenance planning and operator support on the machine itself

- HELLER TPS (Total Productive Services) – Service Agreements for inspection, service and maintenance measures

Control

Combined processing is multi-tasking in metal machining – for the machine, as well as for the control. A machining centre achieves combined milling and turning at the limit only with powerful boring, milling, turning and measuring cycles. That's why, for our C-series 5-axis milling-turning machining centre, we rely on the Siemens SINUMERIK 840D sl state-of-the-art high-performance control.

Siemens SINUMERIK 840D sl

- high-performance control for machining centres that have to meet the highest requirements when it comes to performance and machining precision

- digital drive technology and state-of-the-art system architecture

- SINUMERIK Operate user interface for efficient machine operation

- HELLER Operation Interface for more comfortable operation (as standard for machines with table loading, optional for machines with pallet changer)

- optimally integrated and adapted specifically to the requirements of HELLER machining centres with the MDynamics 5-axis technology package

- integrated HELLER balancing function

- standard for machines with table loading (optionally available with pallet changer)

- main operating unit designed as a console for optimum operating comfort on machines with Siemens control systems

- 24" screen and multi-touch function, optimum for displaying documents and drawings

- HELLER Operation Interface with 4 function areas for extra information at a glance

- practical Xtends HELLER expansions and additional functions

- machine control panel with pushbuttons and 3 overrides for optimum control in all operating situations

- handheld operating unit

- convenient operating panel at workpiece loading station

- HELLER Remote Diagnostic Services (RDS)

- pallet management system for multiple setups

- alternative strategy

- order management

- automatic setting and de-setting sequence

Technical data

| Product selection | CP 8000 | CT 8000 | CP 10000 | ||

|

Positioning range

X/Y/Z | mm | 1,250/1,200/1,400 | 1,250/1,250/1,400 | 1,600/1,400/1,400 | |

|

Rapid traverse speed

X/Y/Z | m/min | 50 | 50 | 45 | |

|

Acceleration

X/Y/Z | m/s² | 4 | 4 | 4/4(3)2)/4 | |

|

Positioning tolerance Tp / At1) X/Y/Z | VDI/DGQ 3441 / ISO 230 | mm | 0.008 | 0.008 | 0.008 | |

| Tool shank | Size | HSK-T 100 | HSK-T 100 | HSK-T 100 | |

|

Chip-to-chip time

t₂,₃ | VDI 2852 | s | 6.3 | 6.3 | 7.1 | |

|

Clamping surface

Nominal size | mm | 800 x 800 | Ø 1,100 | 1,000 x 1,000 | |

|

Workpiece dimension

Diameter x height | mm | Ø 1,250 x 1,400 | Ø 1,810 x 1,400 | Ø 1,400 x 1,600 | |

| Clamping load | kg | 2,000 | 2,000 | 4,000 | |

|

Machine control

Siemens SINUMERIK 840D sl | Siemens | Siemens | Siemens |

( ) = optional values

- = not available

1) = position uncertainty

2) = in conjunction with tilting head

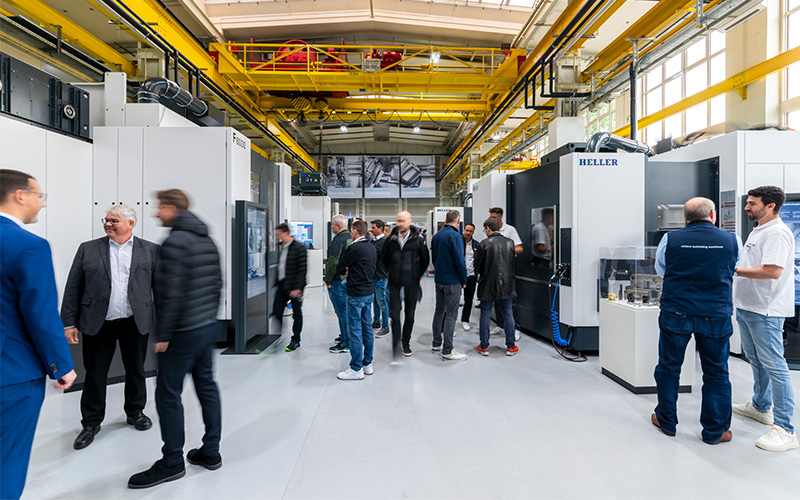

At a glance, our Download Centre offers an extensive range of information materials about our company, our products and services for you to download.

Contact

Contact

Sales & Services

Do you have questions about our products and services? Please get in touch with us, we are here for you! Benefit from our global HELLER network with knowledgeable sales and service contacts located in your region.

Find your nearest personal contact.

No results could be found.

You might also be interested in

HELLER Newsletter

Register now!

The HELLER Newsletter provides you with information about all current topics concerning our company, our products and services as well as upcoming trade shows and events. Register now to make sure you never miss any news from the HELLER Group!