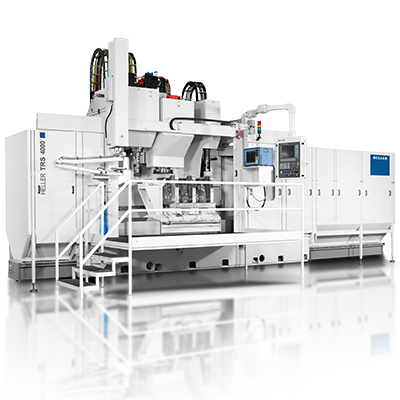

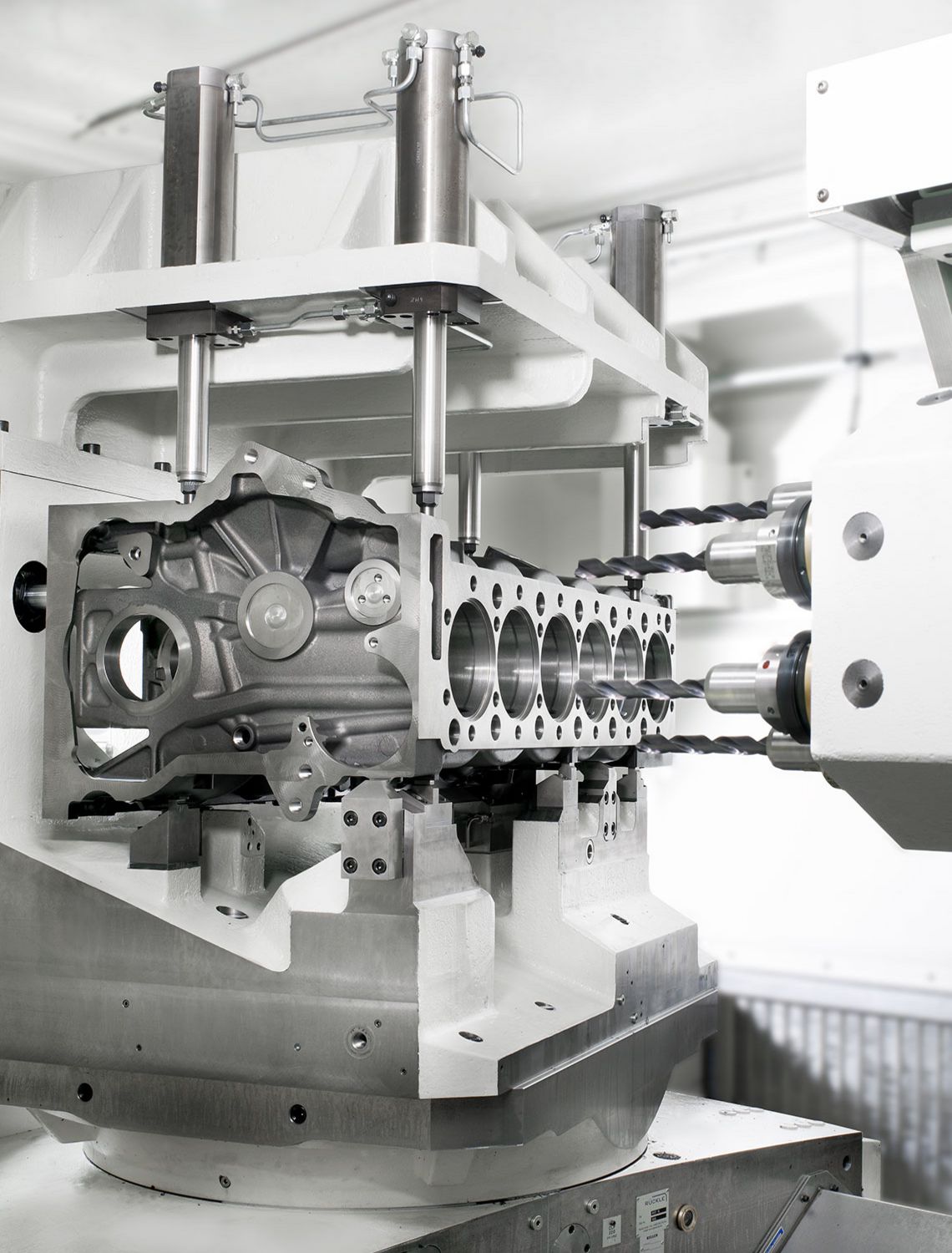

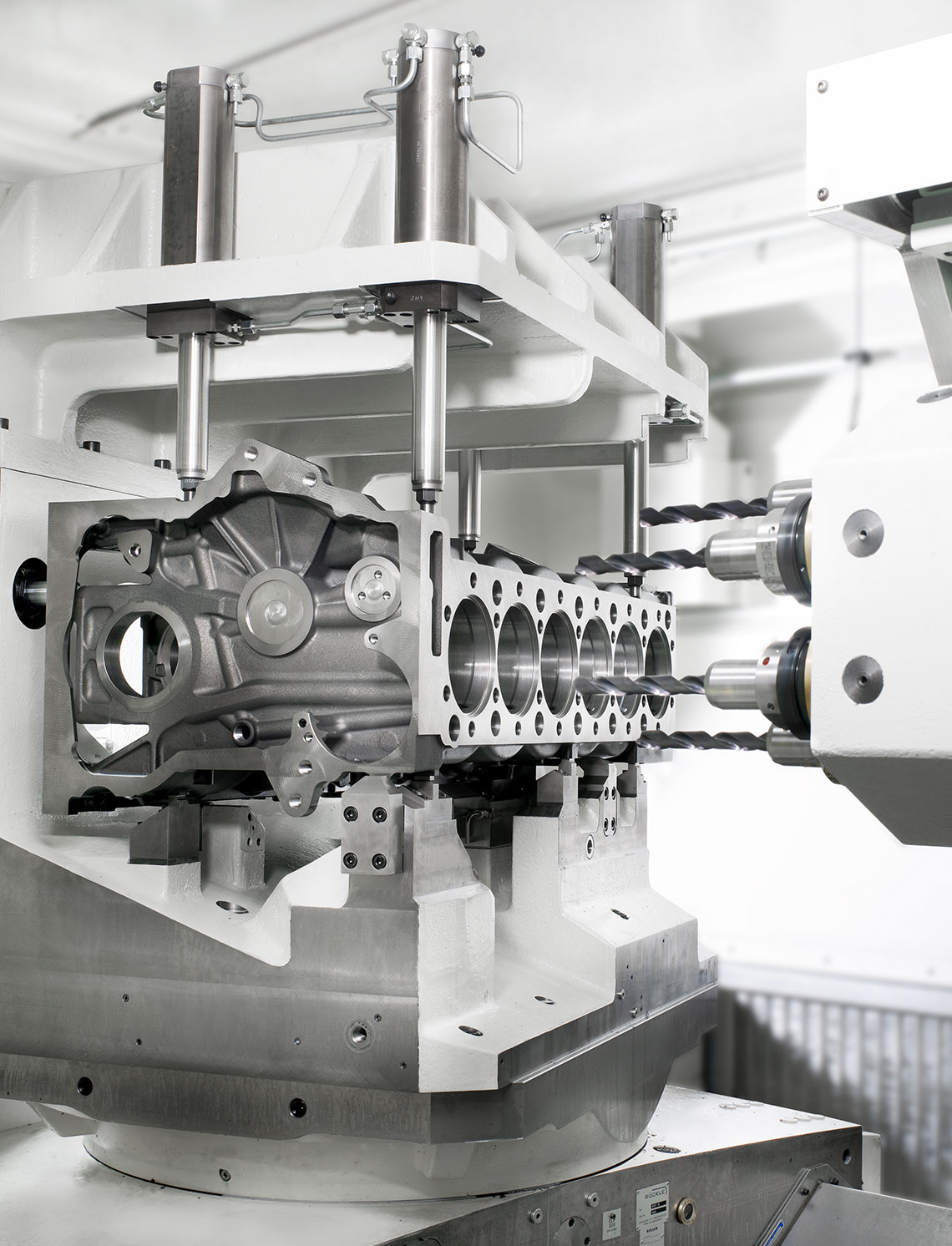

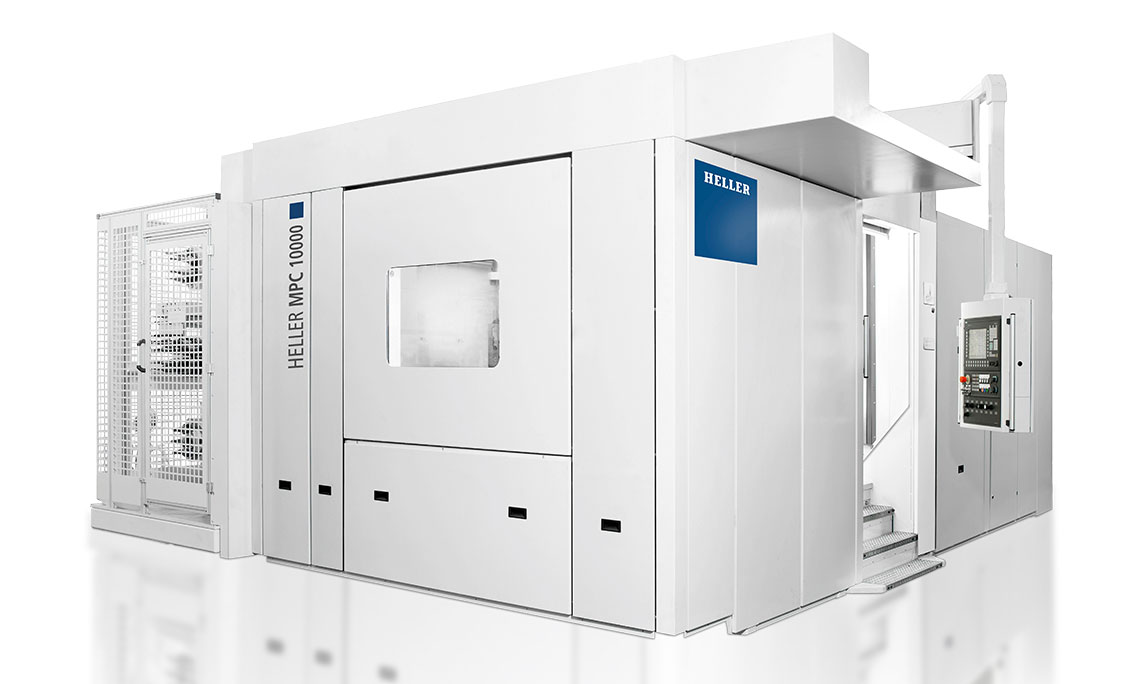

Robust basic structure: cross-bed and travelling column in gated design

- maximum stability in the flow of forces through topology-optimised structural components from steel

- optimised flexibility thanks to the use of application-specific machining heads

- automatic head changer

- magazine for machining heads at the rear of the machine

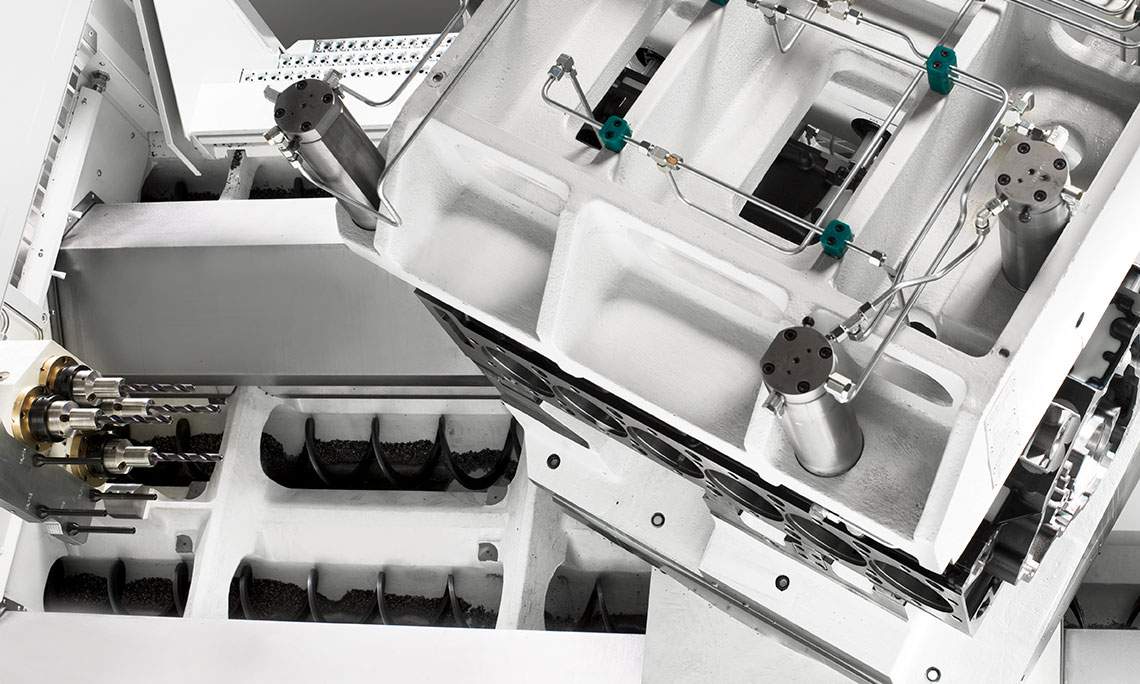

4-axis kinematics with horizontal machining unit

- machine bed carries the X- and the Z-axis in a cross bed arrangement

- the machine column traverses in the X-direction and carries the machining unit

- machining unit traverses in the Y-direction, compactly integrated into the machine column

- NC rotary indexing table (B) or NC swivel table (A) as the 4th axis traverses in the Z-direction and executes the feed movement

Stiffness and optimised feed forces in the feed direction: roller bearing-mounted linear guides and stable YRT bearings in the rotary axes

- linear axes with roller guides, driven by ball screws for a high dynamic

- direct, absolute measuring systems (glass scales in linear axes) for optimised precision and low position tolerance

- NC rotary indexing table with large YRT bearings and automatic clamping for maximum stability and high tilting moments

- NC rotary indexing table (B) with gear drive for high circular milling torque and damping

- NC swivel table (A) with two-sided drive and integrated clamping

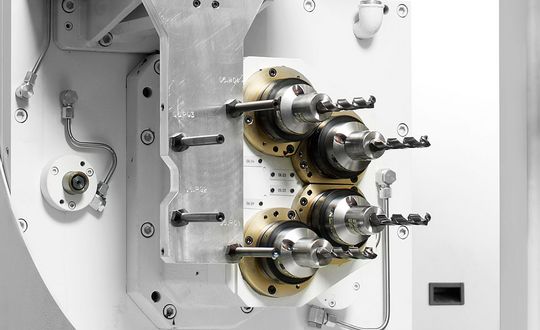

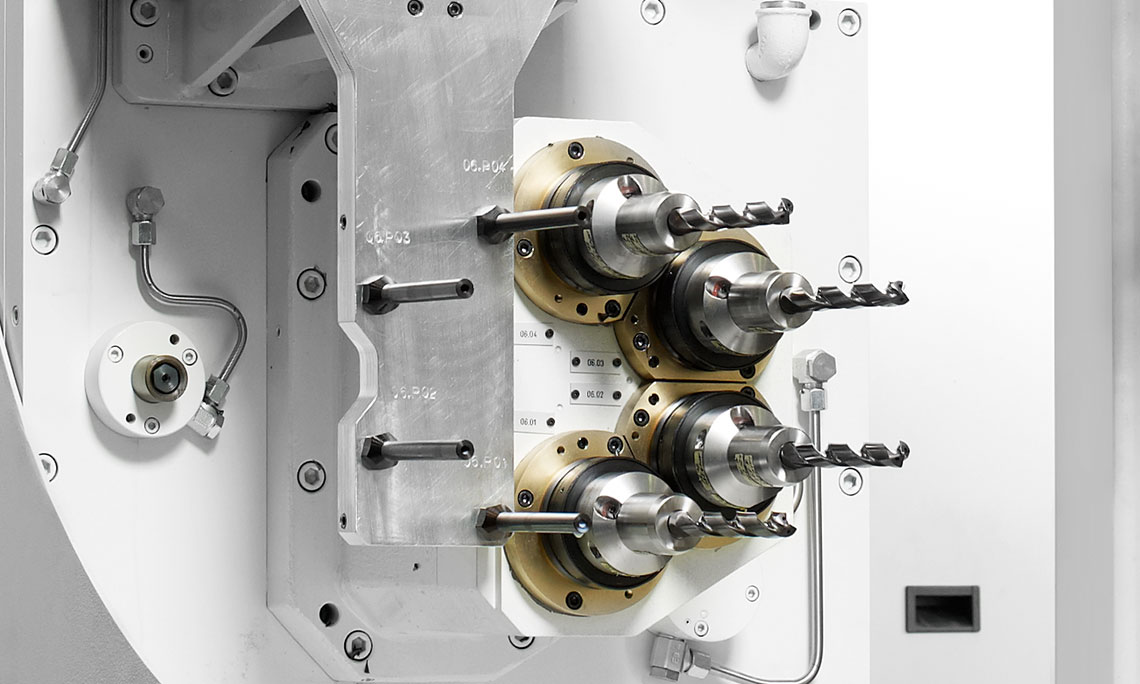

Universal machining unit for automatic mounting of machining heads

- horizontal arrangement for optimal chip fall

- standardised HELLER Interface with 4-point clamping and integrated media transfer

- application-specific heads weighing up to 850 kg

- speed and torque realised in the machining head

Magazine for machining heads

- storage capacity with up to 8 heads

- integrated setting station with easy access for setting using the crane

Automatic changeover of machining heads

- automatic head changer with sliding principle

- short chip-to-chip time, regardless of the head mass

Direct loading in series production

- workpieces loaded into the work area (direct load)

- automatic loading hatch above the work area for loading from above with gantry loader

Module selection of rotary axes

- NC rotary indexing table (B) or NC swivel table (A) as the 4th axis

- optional: integrated 12-point media interface for hydraulic workpiece clamping

Automatic loading and unloading of workpieces

- optimally designed for use in interlinked machines with gantry loader systems

- workpieces loaded into the work area (direct load)

- automatic loading hatch above the work area for loading from above with gantry loader

Contact

Contact

Sales & Services

Do you have questions about our products and services? Please get in touch with us, we are here for you! Benefit from our global HELLER network with knowledgeable sales and service contacts located in your region.

Find your nearest personal contact.

No results could be found.

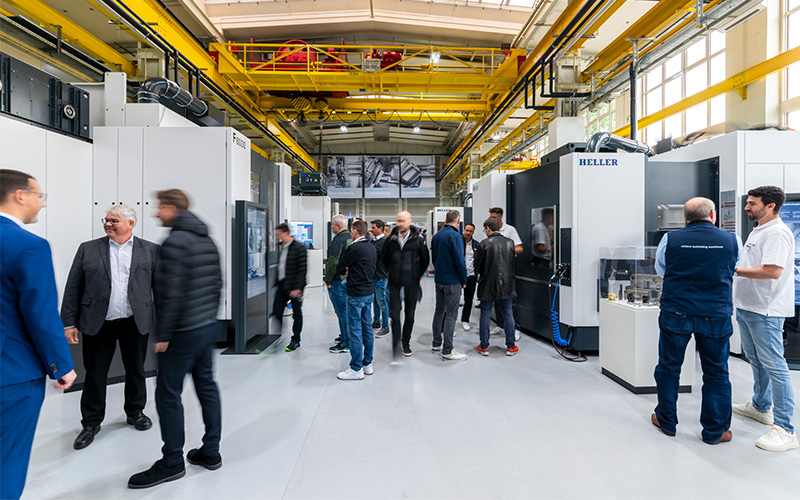

You might also be interested in

HELLER Newsletter

Register now!

The HELLER Newsletter provides you with information about all current topics concerning our company, our products and services as well as upcoming trade shows and events. Register now to make sure you never miss any news from the HELLER Group!