HELLER Services

Lifetime Partnership

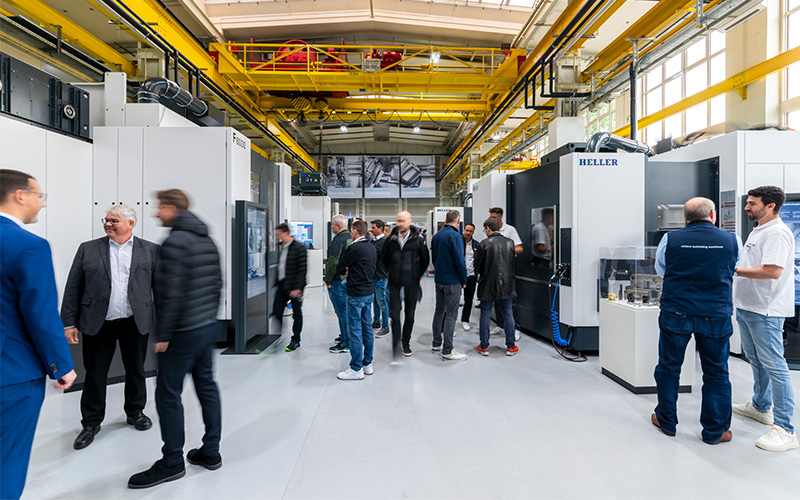

HELLER Services provides you with a comprehensive range of transparent and clearly structured technical services. As a reliable service partner, we support you throughout the entire life cycle of your machine, ensuring its productivity and availability. From project planning to the utilisation phase, right through to the decision about the re-use. To ensure maximum performance and productivity in your manufacturing facility, HELLER machines and services are perfectly in tune.

Our strengths are speed, flexibility and communication

- Located centrally in the UK and integrated into our UK manufacturing facility

- Employing highly skilled technicians who are knowledgeable on the entire Heller range of machines, ensuring they can diagnose issues accurately and provide effective repairs and maintenance

- Offering a quick response time to customer service requests, with the ability to provide on-site support or remote assistance

- £2 million of UK spare parts readily available to minimize downtime, with same day delivery on offer and next day delivery on over 40,000 spare parts from Germany

- Providing a full spectrum of services, including preventive maintenance, troubleshooting, repairs, geometrical inspection, rebuilds and upgrades for all ranges of machines, ensuring comprehensive support for customers

- Tailoring services to meet the specific needs of each customer, whether they operate in industries such as manufacturing, aerospace, or automotive, and adapting service plans to suit the unique requirements of different machines

Our services at a glance

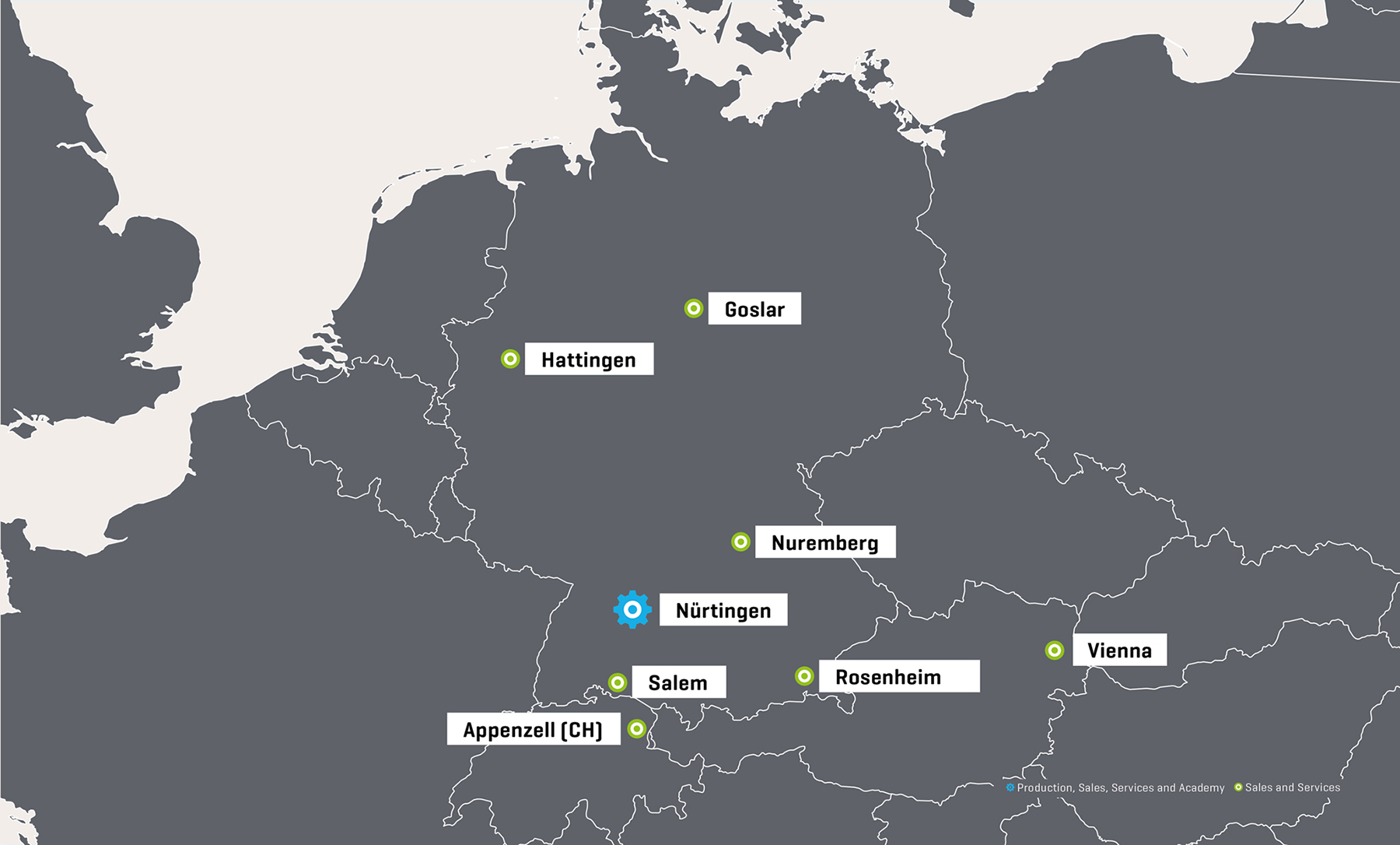

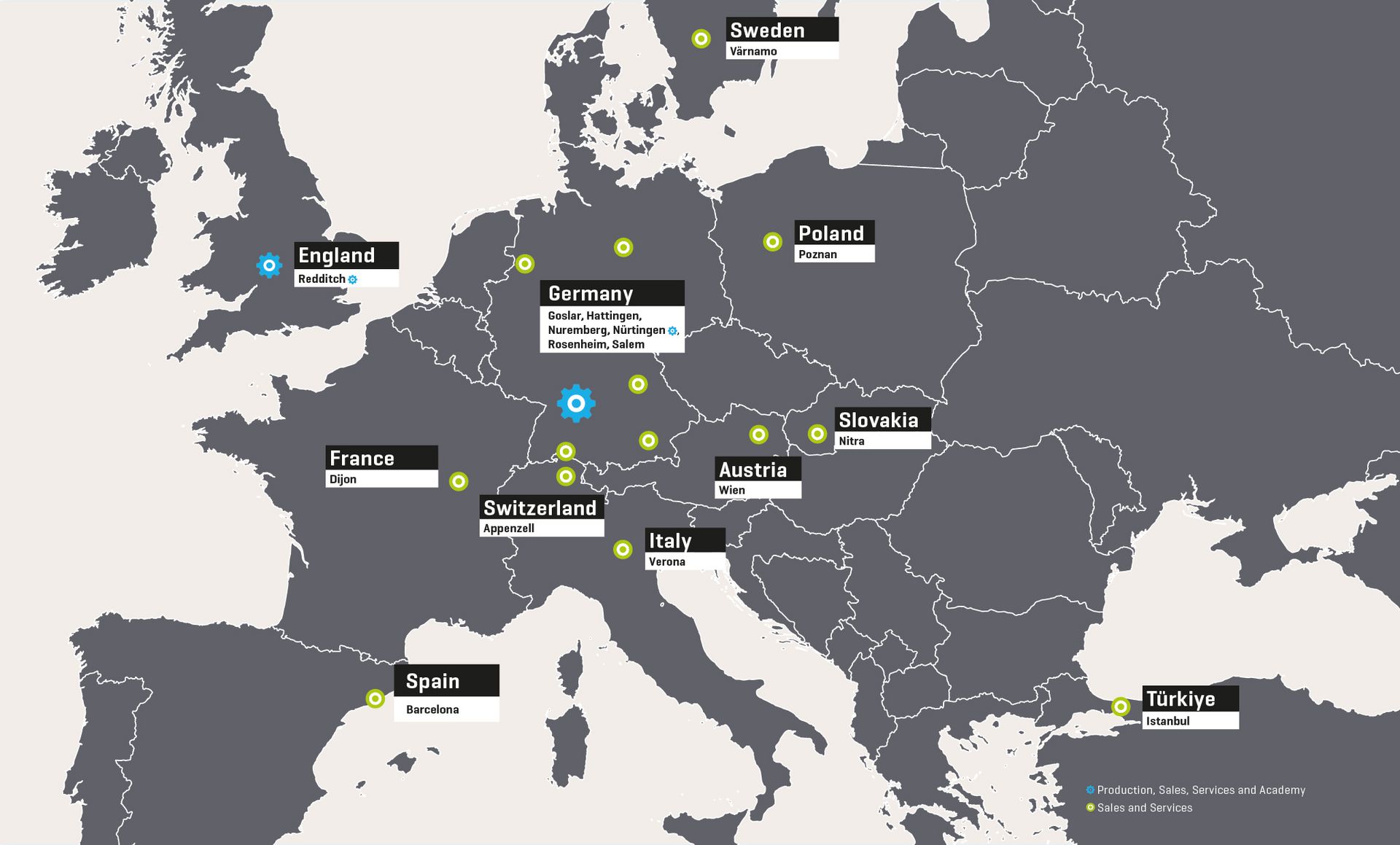

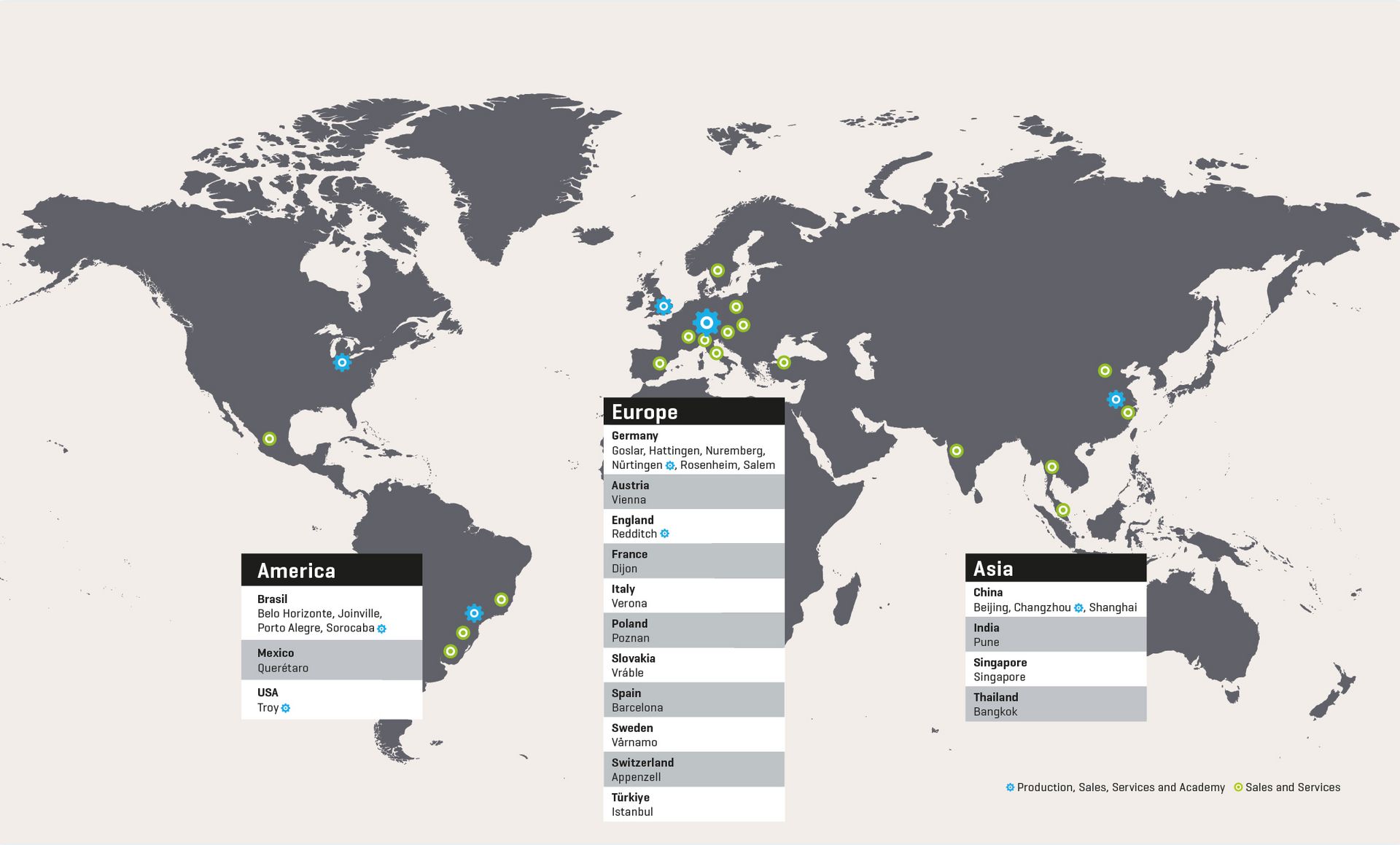

HELLER Service bases

Your expert Service Partner near you

Ready2deliver – Ready4productivity

The quick way to boost your productivity

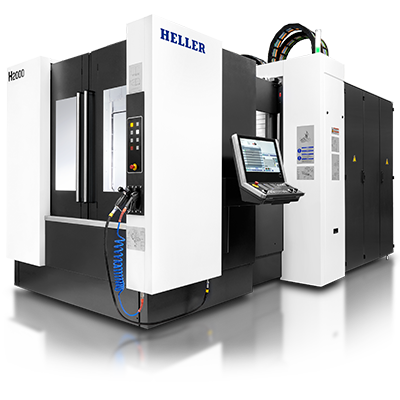

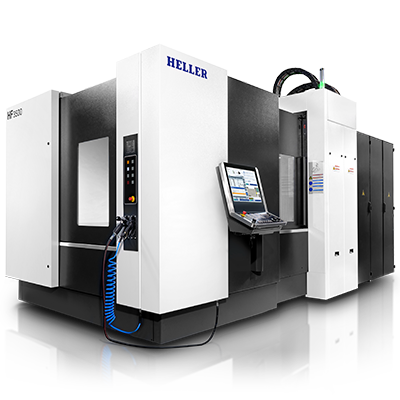

Are you looking for a machining centre, but have no time to put up with long delivery times? Then we have the perfect solution for you: discover the 4-axis and 5-axis machining centres from our H and HF series available at short notice. Pre-configured and available in various specifications – for maximum efficiency and diverse production requirements.

Ready2deliver – Ready4productivity

The quick way to boost your productivity

Are you looking for a machining centre, but have no time to put up with long delivery times? Then we have the perfect solution for you: discover the 4-axis and 5-axis machining centres from our H and HF series available at short notice. Pre-configured and available in various specifications – for maximum efficiency and diverse production requirements.

Contact

Contact

Sales & Services

Do you have questions about our products and services? Please get in touch with us, we are here for you! Benefit from our global HELLER network with knowledgeable sales and service contacts located in your region.

Find your nearest personal contact.

No results could be found.

You might also be interested in

HELLER Newsletter

Register now!

The HELLER Newsletter provides you with information about all current topics concerning our company, our products and services as well as upcoming trade shows and events. Register now to make sure you never miss any news from the HELLER Group!