HELLER solution at Fette Compacting

Maximum precision and productivity increase

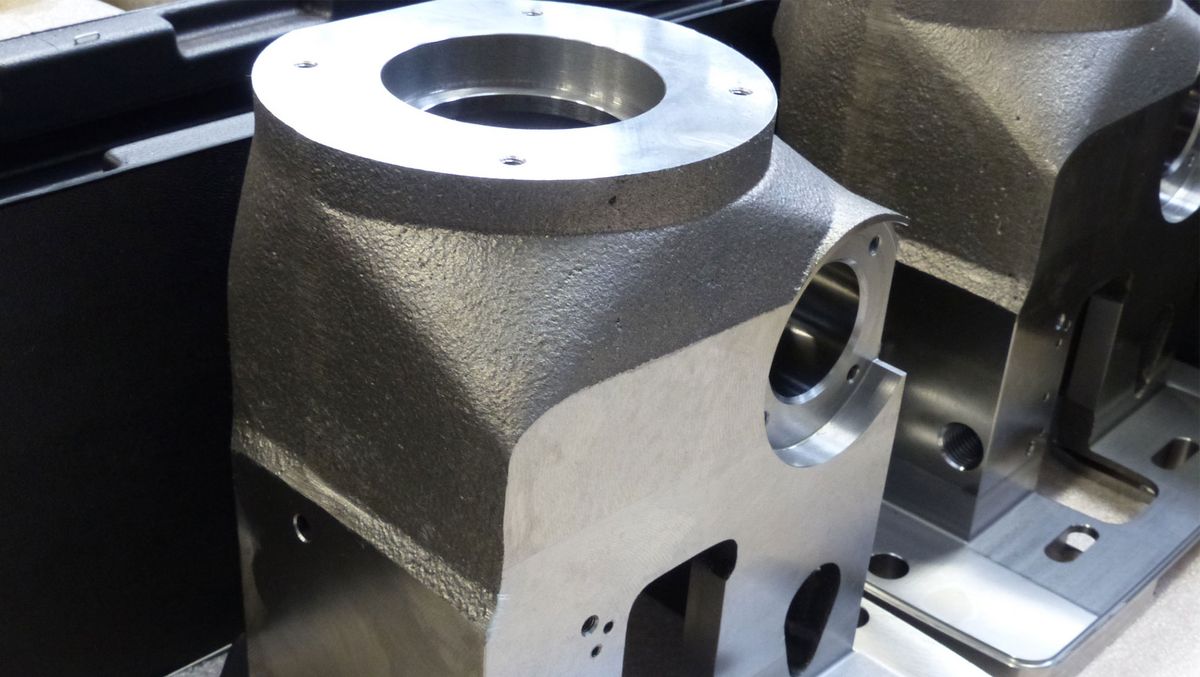

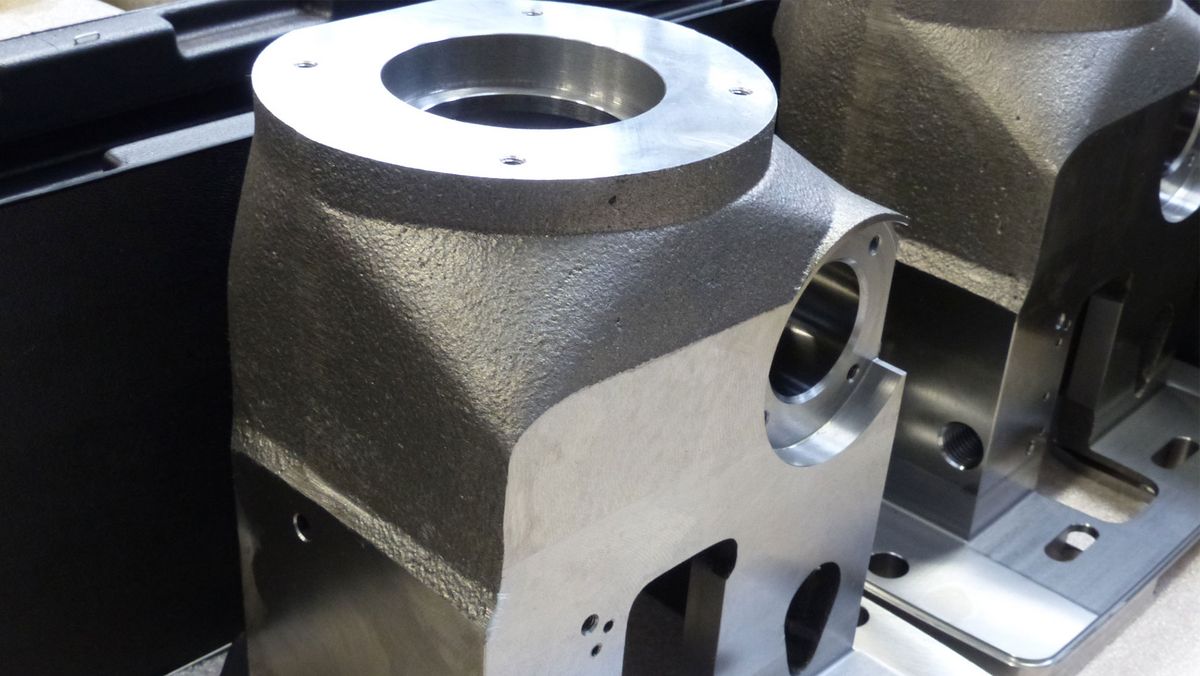

Fette Compacting produces a broad range of parts from diverse materials. Thanks to the fifth axis in the tool, the automation system and a new tool technology, manufacturing costs were cut by 32 percent.

Task

- to increase availability and cut manufacturing costs

- high requirement profile with respect to footprint, table load, automation and interlinkage facilities with a second machine

- precision for tolerance ranges in pitch circles and for bearing seats to within just a few µm

Project scope & solution

- two HELLER FP 6000 5-axis machining centres

- temperature-controlled feed drives, volume compensation and various software features

Result

- machining time reduced to 50 minutes thanks to fewer setups and modified cutting parameters, including shorter setting times

- large series component manufacturing

- technical availability of 98 to 99 percent, further increase expected

Contact

Contact

Sales & Services

Do you have questions about our products and services? Please get in touch with us, we are here for you! Benefit from our global HELLER network with knowledgeable sales and service contacts located in your region.

Find your nearest personal contact.

No results could be found.

You might also be interested in

HELLER Newsletter

Register now!

The HELLER Newsletter provides you with information about all current topics concerning our company, our products and services as well as upcoming trade shows and events. Register now to make sure you never miss any news from the HELLER Group!