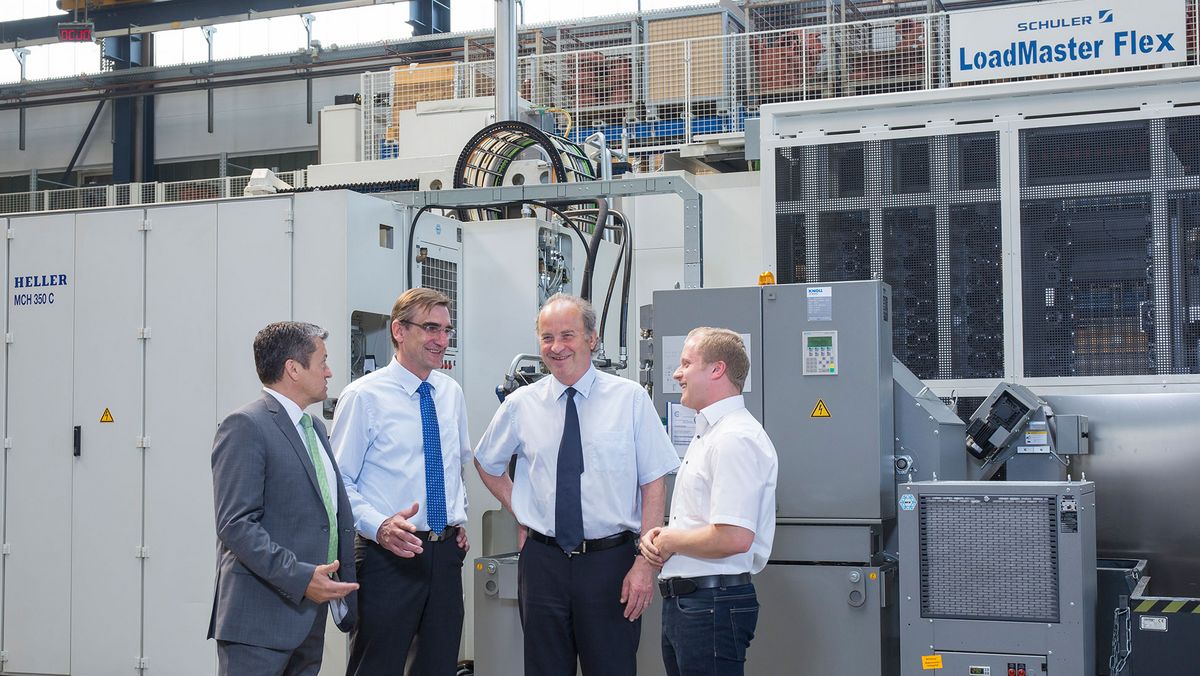

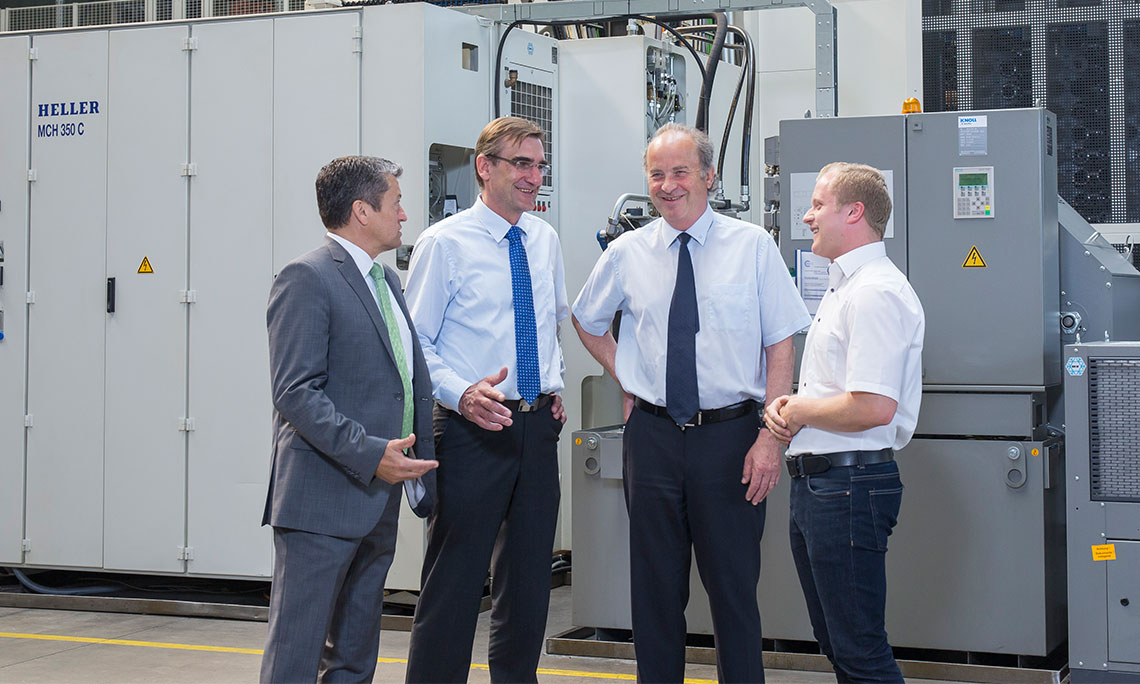

HELLER solutions at H.P. Kaysser

Machines and automation adapted

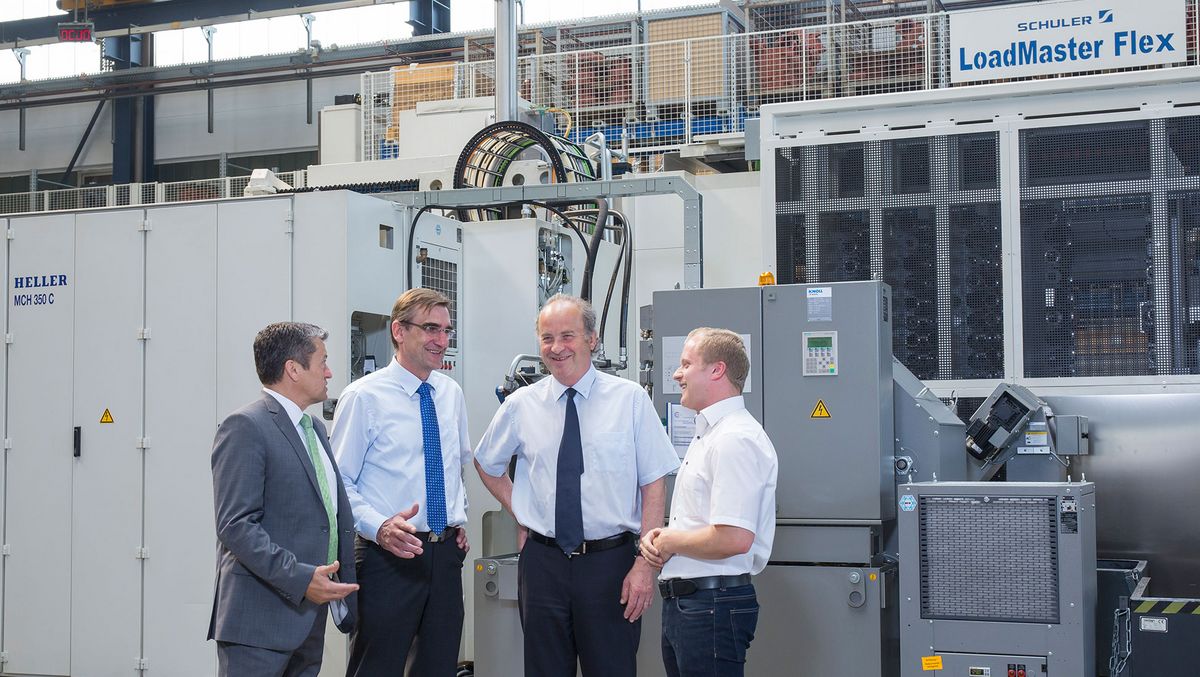

At H.P. Kaysser, leading international sheet metal processor/system supplier, the batch sizes are reducing, while the requirements continue to increase. Long setting times, a large stock and the problem of precise deadline control will all be resolved by the Automation LoadMaster® from Schuler in conjunction with the HELLER MCH 300 and MCH 350-C machining centres.

Task

- to expand a three-layer system at the limits of its capacity, consisting of an automation system with 20 tool pockets and the HELLER MCH 300 machining centre

- to integrate the entire workpiece management strategy into the system

- small to medium batch sizes and just-in-sequence production facility

- enhanced flexibility and productivity

Project scope & solution

- Automation LoadMaster® from Schuler in conjunction with the HELLER MCH 300 and MCH 350-C machining centres

- Automation LoadMaster® offers a storage capacity of 45 machine pallets on 3-level and 77 storage locations for the raw material over 5-level Euro pallets/Euro wire mesh crates

Result

- 50 to 80 percent gain in chip-to-chip times

- machine availability increased from 82 to just on 90 percent

- in the case of long-running items (involving eight to nine hours per workpiece), a machine running time of 600 hours per month already achieved

Contact

Contact

Sales & Services

Do you have questions about our products and services? Please get in touch with us, we are here for you! Benefit from our global HELLER network with knowledgeable sales and service contacts located in your region.

Find your nearest personal contact.

No results could be found.

You might also be interested in

HELLER Newsletter

Register now!

The HELLER Newsletter provides you with information about all current topics concerning our company, our products and services as well as upcoming trade shows and events. Register now to make sure you never miss any news from the HELLER Group!