As an industrial research and development organisation, on behalf of its extensive membership the AMRC strategically benchmarks the machine tool market to identify the most effective production platforms and techniques for different applications. Currently, over several sites it operates more than 60 CNC machine tools, with approximately half a dozen being horizontal-spindle prismatic machining platforms

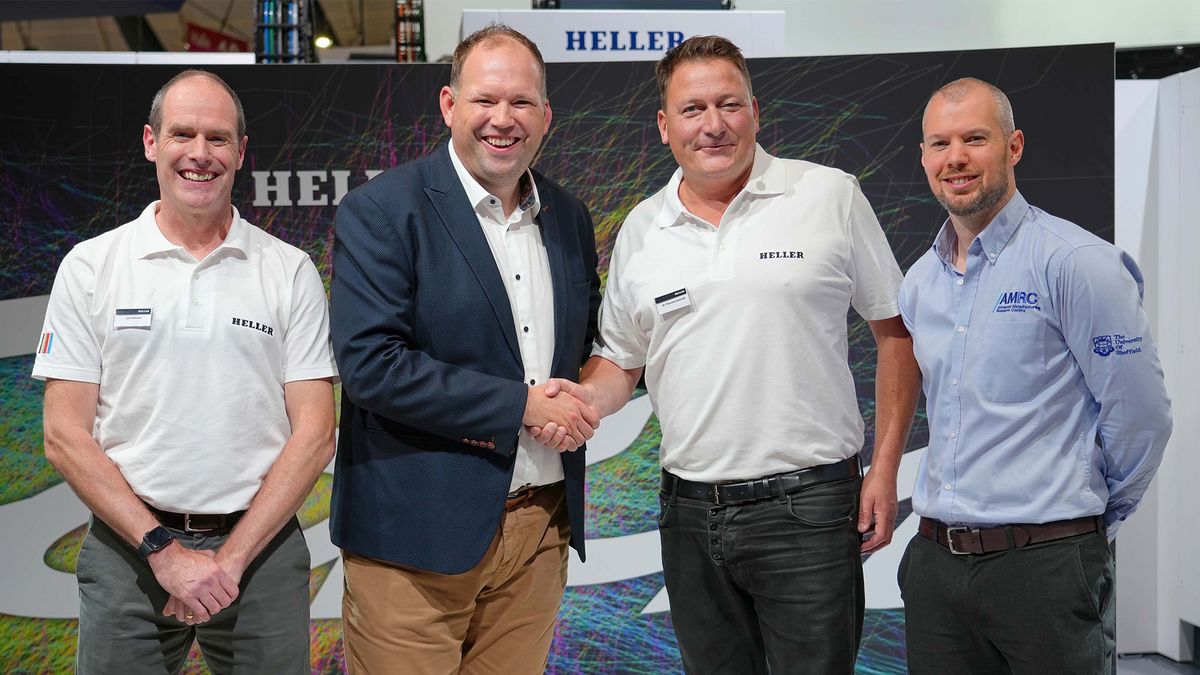

The installation of the HELLER machine bolsters the centre's ongoing efforts to secure high-value jobs within the manufacturing sector in the UK, a crucial aspect of its remit for obtaining grant funding. Many of those jobs are in the aerospace industry. An important facet of the HELLER acquisition will therefore be to transfer the machine brand's renown for high reliability, availability and uptime for volume production in the automotive sector to aerospace applications.

The mill-turn F 6000 will also play a key role in the AMRC’s new autonomous toolroom demonstrator it is developing and demonstrating at its Factory of the Future. More generally, the machine will assist in a series of projects across different research themes and programmes focusing on supply chain challenges, skills shortages, integrating digital technologies throughout the manufacturing process, automating production, adapting it to changing demands, real-time process data analysis, and ecological sustainability.

Tom McCready, Engineering and Operations Manager of the AMRC Machining Group said, "The exceptional capabilities of Heller horizontal machining centres make them well suited to processing hard metals like titanium, crucial for machining structural aircraft components and aero engine parts, for example.

"The F 6000 will be the first machine in the AMRC's Factory of the Future to feature the Siemens SINUMERIC ONE control system, which in combination with HELLER software will provide a valuable asset for our research into network connectivity and manufacturing traceability.

"Beyond its impressive chip removal capacity, the twin-pallet machine is automation-enabled, with the possibility of retrofitting different types of pallet storage systems, opening up possibilities for future development into an autonomous production cell."

In the run-up to the installation of the HELLER machine, there was considerable excitement about its imminent arrival among the AMRC’s more than 100 members, particularly the major players in the aerospace industry such as Boeing, Rolls-Royce and BAE Systems. The F 6000 will serve as a key benchmark for comparing its pivoting spindle head configuration, which among other benefits converts it within a machining cycle into a flexible, universal machining centre, against other types of five-axis machine, such as those with a swivelling trunnion.

Demonstrating the immediate impact of this additional resource, projects had already been lined up for the HELLER machine over the six months prior to its arrival. Machine tool equipment suppliers, manufacturers within their supply chains and OEMs from various industries had all put forward detailed requests. Mr McCready commented that it was an unprecedentedly busy research pipeline for a newly installed machine at the AMRC.

He also emphasised the significant benefit of HELLER’s manufacturing presence in Redditch, where the company produces its 4- and 5-axis machining centres on two flow lines, although not the F 6000. The UK operation boasts extensive experience in design, procurement, service and support in the machine tool sector, as well as in delivering full turnkey production solutions to customers.

You might also be interested in this article: HELLER becomes latest Tier 1 member of the AMRC